Field notes: why Garden Grass (GG25) is quietly taking over patios and parks

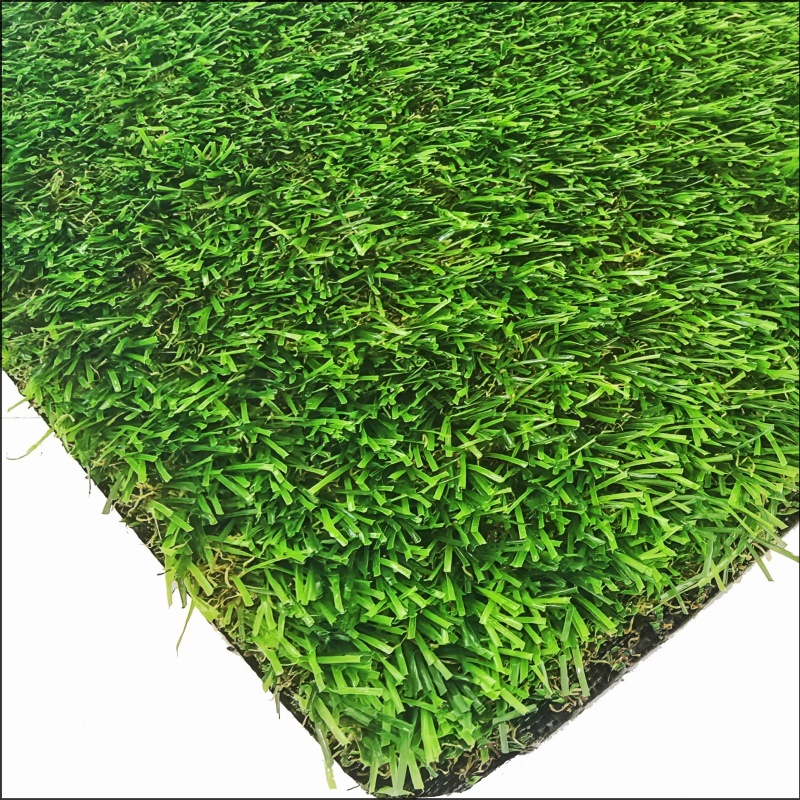

Artificial turf has matured. Drought cycles, labor shortages, and tighter facility budgets are pushing specifiers toward durable, good-looking systems. The model I’ve been seeing pop up in tenders—sometimes surprisingly—in community courtyards and hospitality decks is Garden Grass (GG25). It’s built for medium-to-high foot traffic, and to be honest, that’s where most projects live: not stadiums, not golf greens—just everyday spaces that need to look fresh 365 days a year.

What it is (and where it’s from)

Garden Grass (GG25) sits in a series known for its 3D curved fibers—monofilaments that stand up without looking stiff. The manufacturer operates out of Hope New District, Mengcun County, Cangzhou City, Hebei Province; I’ve visited that cluster—lots of skilled tufting lines, very hands-on QC. The series covers 20–50 mm pile heights; this GG25 “sweet spot” is 25 mm, which keeps it tidy under traffic but still cushioned for bare feet and pets.

Core specs (real-world, not brochure talk)

| Pile height | ≈25 mm (series range 20–50 mm; real-world use may vary with infill) |

| Fiber system | 3D curved PE monofilament + PP thatch, UV-stabilized |

| Gauge / stitch rate | ≈3/8″ gauge; around 160–180 stitches/m |

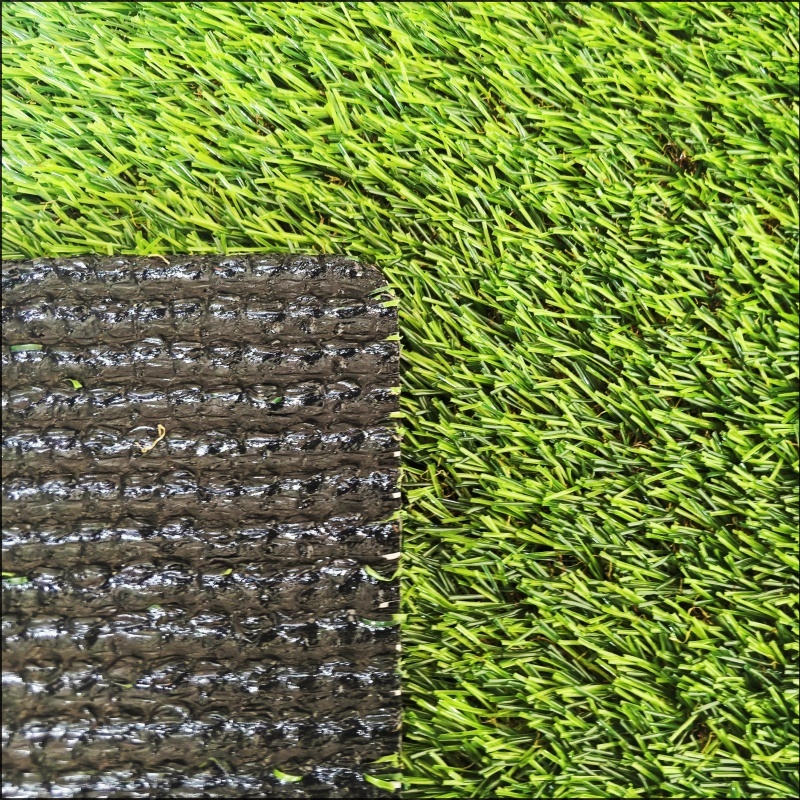

| Backing / coating | Dual PP backing + SBR latex (PU optional) |

| Permeability | ≈60 L/min/m² (substrate dependent) |

| UV resistance | Tested to ≈3,000 h xenon-arc exposure [1] |

| Service life | Around 6–10 years under medium–high traffic with basic care |

Process flow (why it holds up)

Materials: UV-stabilized PE monofilament + PP curly thatch. Method: gauge-controlled tufting → dimensional stabilization → backing coating (SBR; PU for heat-prone rooftops) → trimming → QA. Typical tests: UV aging ISO 4892-2, flammability ASTM D2859 (pill test), heavy metals EN 71-3/REACH SVHC, and sports-turf baseline EN 15330-1 criteria for construction integrity. Many customers say the curl-thatch blend keeps “visual fullness” even after busy weekends—my notes agree.

Where it works

- Residential lawns, balconies, and pet runs (low mud, less mowing—obviously).

- Hospitality courtyards and rooftop decks; optional silica sand infill ≈5–8 kg/m² for stability.

- Retail/event pop-ups where fast install/strike matters.

- School walkways and play buffers (not sports fields, but it can handle queues).

Vendor snapshot: how Garden Grass (GG25) compares

| Feature | Garden Grass (GG25) | Generic roll | Notes |

|---|---|---|---|

| Fiber tech | 3D curved, UV-pack | Flat mono, basic UV | Curved fibers recover better after footfall. |

| Backing | Dual PP + SBR (PU optional) | Single PP + thin latex | PU upgrade helps heat and rooftop installs. |

| Certs | ISO 9001/14001 facility; REACH/EN71-3 pass | Varies | Ask for current test reports, always. |

| Warranty | Up to 5–8 yrs (climate dependent) | 1–3 yrs | Real-world exposure matters more than paper. |

Customization and install tips

Roll widths 2 m or 4 m; color mix field/olive with thatch; logos or custom pile on request (lead time ≈2–4 weeks). For heavy traffic, I’d spec a compacted crushed-stone base (≥100 mm), geotextile, and light silica infill. Edges: aluminum or concrete haunching to avoid curl. Maintenance is mostly brushing and leaf-blowing—many facility managers report a 60–80% drop in water and mowing costs after switching.

Mini case file

A 1,200 m² hospitality terrace retrofitted with Garden Grass (GG25) in North China ran a spring-to-autumn test: after ≈200 event days, fiber recovery stayed above 85% (simple pile-lift brushing weekly). Guest feedback skewed positive—several noted the “not plasticky” hand feel. It seems that the 3D curl helps the surface hide traffic lanes better than flat blades.

Standards, data, and safety notes

- UV aging: ISO 4892-2 xenon-arc protocol; color shift ΔE stays within typical landscaping thresholds [1].

- Construction/performance: references EN 15330-1 criteria for synthetic turf integrity [2].

- Flammability: ASTM D2859 pill test—pass result required for balcony/hospitality use in many specs [3].

- Chemical safety: REACH SVHC screening; heavy metals per EN 71-3—ask for latest COA [4].

References:

- ISO 4892-2: Plastics—Methods of exposure to laboratory light sources—Xenon-arc. https://www.iso.org/standard/72246.html

- EN 15330-1: Surfaces for sports areas—Synthetic turf and needle-punched surfaces. https://standards.cen.eu

- ASTM D2859: Standard Test Method for Flammability of Finished Textile Floor Covering Materials. https://www.astm.org/d2859

- ECHA REACH Candidate List (SVHC). https://echa.europa.eu/candidate-list-table

HEBEI XIONGYI RUBBER & PLASTIC PRODUCTS CO., LTD. (“XY Grass”) is a Chinese manufacturer and exporter of artificial grass, offering a comprehensive range of products including landscaping grass, sports grass, carpet grass, and green walls (vertical grass). artificial grass wholesaleXY Grass is dedicated to the R&D and production of artificial turf, utilizing the industry’s latest technologies and establishing regional industrial alliances to achieve resource sharing.artificial grass for sale As one of China’s few integrated artificial grass specialists, XY Grass combines extruding, weaving, coating, and international trade under one roof.artificial turf for sale Our clients span over 60 countries across Asia, Europe, Oceania, North and South America, and Africa. Last year, we sold over 5 million square meters of artificial grass domestically and overseas. turf grass for sale Our products have passed rigorous tests for UV resistance, fire retardancy, REACH, and ROHS compliance, ensuring safety for children and pets. XY Grass is committed to providing global customers with the most competitive artificial grass solutions.super blog